SOLDER ANALYSIS

Analysis Programs For New Solders As Well As Existing Pot Metal

• Customer Assurance To Minimize Pot Contamination

• Increase Cost-Effectiveness And Profitability

Metallic Resources offers a complete range of value-added solder analytical services to printed circuit board assembly and fabrication businesses at no charge. Each and every order that is shipped from the manufacturing plant includes a lot number, a “Certificate of Conformance”, and a “Certificate of Analysis”. The Certificate of Conformance details the lot number and all relevant specifications either met or exceeded. The Certificate of Analysis shows the exact percentages of component metals.

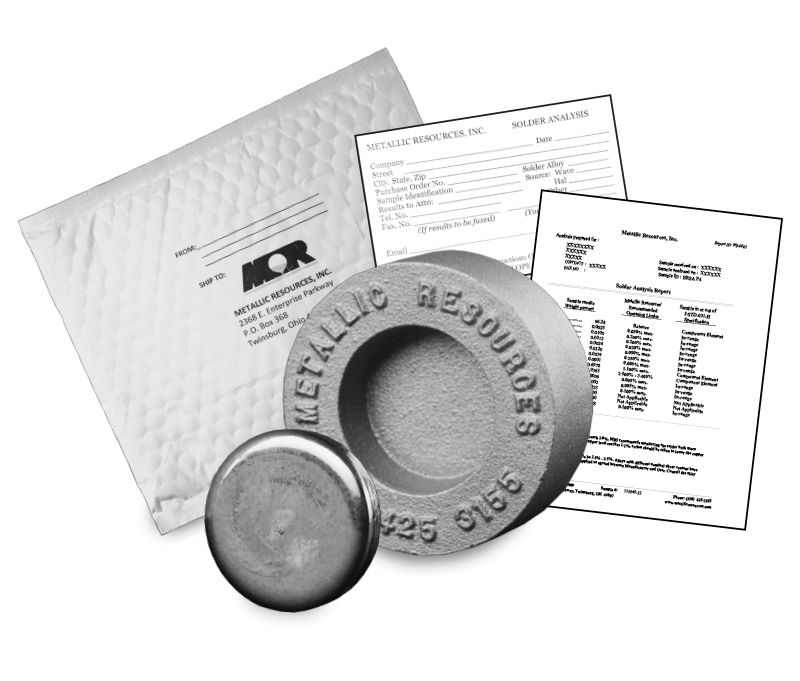

Customers are provided informational cards and mailers to return solder samples to Metallic Resources. The samples are then analyzed spectrographically to determine concentrations for the following elements: arsenic, antimony, gold, iron, nickel, bismuth, aluminum, copper, silver, zinc, cadmium, indium, sulfur, and phosphorus in addition to tin and lead. Metallic Resources provides solder pot analyses when requested at no charge with results faxed to the customer within 24 hours of receipt of the sample.

Metallic Resources’ analytical services are most often used to assure the solder pot has not become contaminated with other metals. Periodically testing the solder will insure the correct balance of tin/lead is being maintained to assure superior solder performance and that the solder bath has not become contaminated with deleterious agents.

Printed circuit board fabricators and assemblers are assured of high quality solder in the pot, constantly kept within specification ranges. Rates of rejection are reduced, thereby creating a more cost-effective and profitable manufacturing process. Many other solder manufacturers provide analytical services, but often charge the customer and take at least a week to provide analytical results; in the meantime, if the pot is contaminated, a week’s worth of production using contaminated solder may result.

Solder Pot Analysis Program

We

Provide unlimited free solder analysis (normally $250 per analysis) to customer who purchase our bar solder or send us their solder dross.

We

Provide free sample molds and solder analysis kit to customer who purchase our bar solder or send us solder dross.

It’s

Important to monitor your solder bath to ensure that it stays within required industry J-Standards.

Assay Results

Within 1-2 business days from time of arrival at Metallic Resources.